Estimating the 5 Ton Rice Mill Project Cost in India

5 Ton Rice Mill Project Cost: Setting up a 5-ton per hour (TPH) rice mill in India represents a significant commercial venture, moving beyond small-scale operations into a medium to large-scale industrial setup. This capacity allows for substantial daily processing, catering to larger regional markets or even export demands. However, the “cost” of such a project is not a single figure but a composite of various components.

At Ricetec Machinery, we provide comprehensive solutions for rice milling, and understanding the complete project cost is crucial for our clients. This guide will break down the typical expenses involved in establishing a 5 TPH rice mill plant in India.

Understanding a 5 TPH Rice Mill

A 5 TPH rice mill implies the capacity to process 5 tons of raw paddy into milled rice every hour. This translates to roughly 40-50 tons per 8-10 hour shift, or potentially 100-120 tons per 24-hour cycle if operating continuously. Such a plant is almost always fully automated, incorporating a series of sophisticated machines to ensure high efficiency, minimal grain breakage, and superior finished rice quality.

Key Cost Components of a 5 TPH Rice Mill Project

The overall cost of a 5 TPH rice mill project can be broadly categorized into the following segments:

1. Plant and Machinery Cost (The Core Investment)

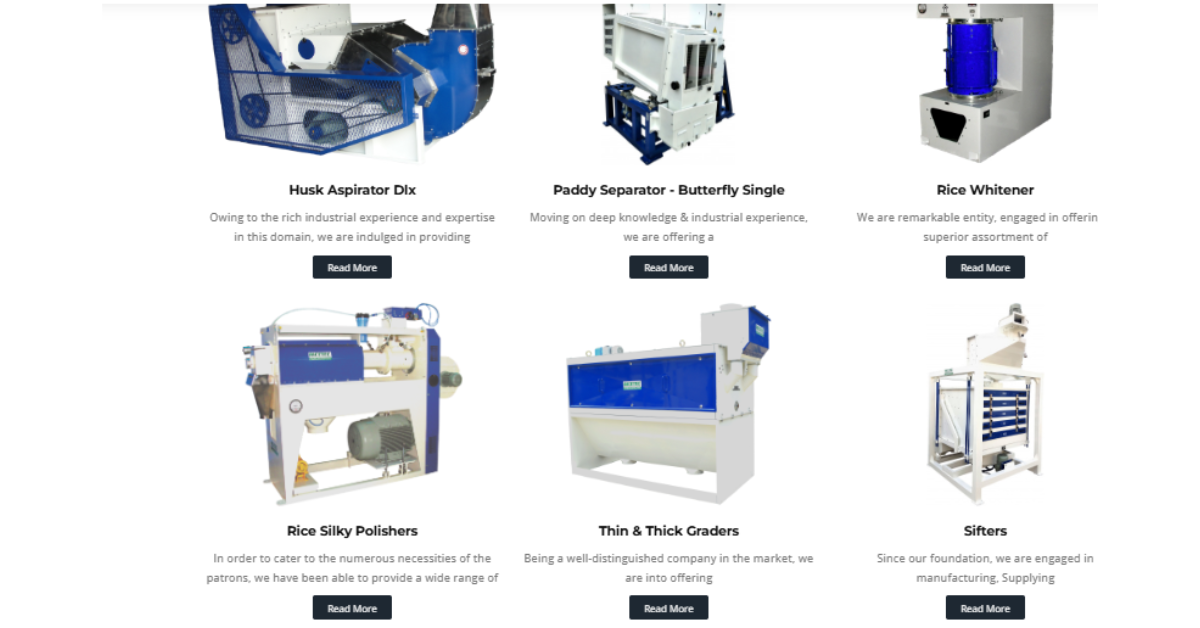

This is the largest component of the project cost. For a fully automatic 5 TPH plant, you’ll need a comprehensive set of machinery, including:

- Paddy Receiving and Pre-Cleaning:

- Paddy intake pits

- Pre-cleaners (for removing large impurities like straw, stones, mud lumps)

- Paddy de-stoners (for removing stones that are similar in size to paddy)

- Aspiration systems and dust collectors

- Paddy Processing:

- Paddy de-huskers (shellers, typically rubber roll type)

- Paddy separators (for separating unhusked paddy from brown rice)

- Rice whiteners/polishers (multiple stages for optimal bran removal and whiteness)

- Mist polishers/silky polishers (for a superior, glossy finish)

- Post-Milling & Sorting:

- Rice graders (to separate whole rice from broken rice by size and shape)

- Color Sorters (optical sorters that remove discolored grains, chalky grains, and foreign materials, significantly enhancing final rice quality and value)

- Conveying Systems:

- Bucket elevators, screw conveyors, pneumatic conveying systems (for efficient material transfer between machines).

- Control Panel:

- Centralized electrical control panel with PLC (Programmable Logic Controller) for automated operation and monitoring.

- Other Essential Equipment:

- Weighing scales (for raw paddy and finished rice)

- Bagging and stitching machines

- Air compressors (for pneumatic systems and color sorters)

- Drying systems (if you plan to dry paddy before milling, especially for parboiled rice, this can be a separate, significant cost)

- Rice husk handling systems (for collecting and potentially utilizing husk as fuel or for other by-products)

Estimated Cost for Plant & Machinery: For a fully automatic 5 TPH rice mill plant in India, the cost for the machinery alone can typically range from ₹45 lakhs to ₹80 lakhs, depending on the brand, level of automation (e.g., number of whitening stages, sophistication of color sorter), and inclusion of specific features like mist polishers or integrated drying solutions. Some advanced or imported systems could even push this higher.

2. Land and Civil Works

- Land Cost: This is highly variable based on location (rural vs. urban, proximity to roads, raw material source). A 5 TPH mill will require a substantial area for the main milling building, raw material storage (paddy godown), finished goods storage, administrative block, and utility areas.

- Estimated Cost: Can range from ₹20 lakhs to ₹1 crore or more, depending on the area (e.g., land in prime agricultural zones or industrial parks vs. remote rural areas).

- Building & Civil Work:

- Construction of the main milling plant building, godowns for raw paddy and finished rice, administrative office, laboratory, utility rooms, security cabin, internal roads, drainage, and compound wall.

- Estimated Cost: Can range from ₹50 lakhs to ₹1.5 crore, depending on the quality of construction, building area, and local construction costs.

3. Utilities and Infrastructure

- Electrical Installation:

- Transformer, power cabling, internal wiring, control panel setup, lighting, and electrical fittings. A 5 TPH mill will require substantial three-phase power.

- Estimated Cost: ₹10 lakhs to ₹30 lakhs.

- Water Supply:

- Borewell, water storage tanks, piping, and water treatment (if necessary).

- D.G. Set (Diesel Generator):

- For power backup to ensure continuous operation, essential in areas with unreliable electricity.

- Estimated Cost: ₹5 lakhs to ₹15 lakhs (depending on capacity).

- Fire Fighting Equipment:

- Fire extinguishers, hose reels, and potentially a fire suppression system as per safety regulations.

- Effluent Treatment Plant (ETP):

- If any water is used in processes like parboiling, or if there’s significant wastewater.

- Dust Collection System:

- While individual machines have some dust collection, a centralized system for overall plant hygiene is often required.

4. Miscellaneous Fixed Assets

- Office Furniture & Fixtures:

- Computers & IT Equipment:

- Laboratory Equipment: For quality testing of paddy and milled rice.

- Material Handling Equipment:

- Forklifts, trolleys for internal movement of goods.

- Vehicles: (Optional, but often a truck for procurement and distribution)

5. Pre-Operative and Contingency Costs

- Consultancy Fees: For project reports, design, and engineering.

- Licenses & Permits: Various government licenses (Pollution Control Board, factory license, trade license, etc.) and their associated fees.

- Project Management Fees:

- Installation & Commissioning Charges: For setting up and testing the machinery.

- Operator Training: For your staff to efficiently run and maintain the plant.

- Trial Run Expenses: Cost of paddy for initial testing.

- Contingency: An essential buffer of 5-10% of the total project cost to cover unforeseen expenses.

6. Working Capital (Operational Costs)

This is not part of the fixed project cost but crucial for the business’s initial months of operation.

- Raw Material (Paddy) Stock: Initial procurement of sufficient paddy to ensure continuous operation. This can be a very large sum depending on market prices.

- Salaries & Wages: For skilled and unskilled labor.

- Electricity Charges:

- Fuel Costs: For generators.

- Maintenance & Spares:

- Packaging Materials: Bags, labels.

- Transportation Costs:

- Marketing & Selling Expenses:

Estimated Total 5 Ton Rice Mill Project Cost in India

Considering all the above components, a realistic total estimated cost for setting up a fully automatic 5 TPH rice mill plant in India can range significantly:

- Low to Mid-Range: ₹1.5 Crores to ₹3 Crores

- Mid to High-End (with advanced features, prime location, modern civil work): ₹3 Crores to ₹5 Crores or more

Note on Cost Variation:

- Automation Level: A fully automated plant will be significantly more expensive than a semi-automatic one.

- Brand of Machinery: Reputable international brands or top Indian manufacturers might have higher prices but often offer better technology, durability, and after-sales support.

- Location: Land and construction costs vary drastically across states and regions in India.

- Inclusion of Drying/Parboiling: Adding a parboiling section and modern drying systems will substantially increase the project cost.

- Customization: Any specific customizations or unique requirements will add to the overall expense.

Return on Investment (ROI) Considerations

While the initial investment is substantial, a 5 TPH rice mill can offer an attractive ROI due to:

- High Processing Capacity: Leading to large volumes of output.

- Improved Head Rice Yield: Modern machinery minimizes breakage, maximizing the valuable whole rice percentage.

- Superior Quality: Color sorters and advanced polishers allow you to produce premium quality rice, fetching better market prices.

- By-product Utilization: Selling rice husk (for fuel or power generation), bran (for oil extraction or cattle feed), and broken rice (for various food products or industries) can provide significant additional revenue streams.

- Reduced Labor Costs: Automation lowers the dependency on manual labor.

Ricetec Machinery: Your Partner in Success

At Ricetec Machinery, we specialize in designing, manufacturing, and installing high-performance rice milling plants. We can provide detailed project reports, machinery specifications, and expert consultation to help you accurately estimate the 5 TPH rice mill project cost tailored to your specific requirements. Our focus is on delivering efficient, durable, and profitable solutions that ensure a strong return on your investment. Contact us today to discuss your vision for a successful rice milling operation.